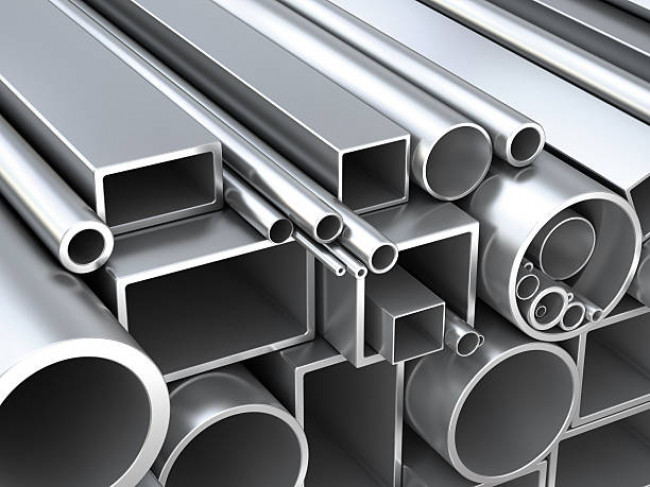

Square Hollow Section (SHS) steel is a versatile construction material used in various industries. Its unique design, which features a square, hollow cross-section, makes it an ideal choice for many structural applications. In Malaysia, hollow section suppliers play a crucial role in providing this steel product to various sectors. This blog will explore the features, benefits, and applications of SHS steel, and why it’s an excellent choice for construction projects. Additionally, we'll highlight the importance of finding the right steel hollow section supplier Malaysia.

What is Square Hollow Section Steel?

Manufacturers create SHS steel as a type of metal profile with a square cross-sectional shape, using high-strength materials and offering it in many sizes. Users choose SHS steel for its strength, flexibility, and usability in various structural and mechanical applications.

Key Features of Square Hollow Section Steel:

Uniform Strength: SHS steel is also uniform in strength throughout the entire surface. This makes it reliable in any load-bearing application.

Lightweight yet Strong: SHS steel appears to be lightweight but gives a lot of strength. This provides an excellent material for structures wherever weight saving is essential.

Aesthetically Appealing: Its clean sharp edges make SHS steel aesthetically appealing. This feature is beneficial in projects where both strength and aesthetics matter.

Corrosion Resistance: SHS steel is often coated or treated to enhance corrosion resistance. It thus serves for long period under most environmental conditions.

How is SHS Steel Produced?

Manufacturers mostly produce Square Hollow Section steel through either cold rolling or hot rolling. In this process, they roll the steel into a tube and then weld it along its length. This welding process ensures that the SHS steel retains structural homogeneity across all dimensions.

Benefits of Using Square Hollow Section Steel

Selecting the right material for your project can make or break its delivery. Some benefits of SHS steel are that it is popularly utilized for the users and its hollow section suppliers.

High Structural Efficiency:

SHS steel is designed to provide uniform strength in all directions. This would result in its strength and structural efficiency to sustain heavy loads before collapsing. The hollow structure is also material-use-efficient, which inherently makes it cheaper than solid steel sections.

Versatile Application:

Whether for industrial, commercial, or residential construction, SHS steel has wide applications. It is applied in the following: frameworks, columns, supports, and other structural components that bear any load. The square shape also does well in fitting into various designs and architectural layouts.

Ease of Fabrication and Installation:

One of the most striking features of SHS steel is that it is very easy to fabricate. You can cut, drill, and weld the material quite conveniently to suit almost all construction requirements, allowing you to complete the construction quickly and save on labour costs.

Cost-Efficient:

The hollow structure of SHS steel means that this element requires less material than similar solid steel sections. This reduces costs and still offers the same level of performance. Additionally, the lightweight design minimizes transportation costs, particularly when businesses source it from a steel hollow section supplier in Malaysia.

Durability and Longevity:

SHS steel is resistant to environmental stressors like corrosion and weathering. This means that structures made from SHS steel will last longer and necessitate less maintenance over time.

Standard Applications of SHS Steel

The versatility the SHS steel offers places it in several applications. Here are the major applications below.

Structural Framing:

SHS steel is preferably used in the construction of building frameworks. This is because its strength and lightweight capabilities adapt it well for the support of loads on high-rise as well as low-rise buildings.

Industrial Applications:

High-strength and tough materials are in wide demand in such industries, particularly the automotive, shipbuilding, and machinery-building industries.

Architectural Design:

Many architects employ SHS steel for aesthetic appeal and smooth lines. Architects largely use SHS steel in modern architectural designs for constructing bridges, staircases, and exterior features.

Identifying the Reputed Hollow Section Manufacturers

When using SHS steel, you must work with suppliers that you trust to get the job done right. Since Malaysia happens to be one of those countries that supplies good quality SHS steel, you should consider these issues below when choosing a supplier that will match your standards:

Quality of the Material:

From your chosen supplier, ensure that the SHS steel supplied is of high quality. It will not only perform better but also stand longer conditions as well.

Size and Dimension Available:

Determine a supplier that will cover a wide range of size and dimension options for SHS steel so you can have the option for an SHS that suits your project.

Reputation and Experience:

Always choose a supplier that will be known and well-experienced in their trade. A company that had existed for several years with plenty of experience with supplying SHS steel to its Malaysian clients stand a good chance of having quality and service standards consistently.

Why Choose Steel Hollow Section Suppliers?

Malaysia has several renowned hollow section suppliers in the region. These suppliers offer SHS steel in several grades and dimensions which also makes it easy for businesses to source the precise material needed. Malaysian steel hollow section suppliers also gain popularity over competitive pricing and quality commitment.

Benefits from Malaysian Hollow Section Suppliers

Local Accessibility: There is direct accessibility to the material without the pressures associated with importing products.

Experience: Generally, the local suppliers of SHS steel have experience dealing with SHS steel.

Custom Fabrication: Most suppliers offer customization services whereby a business can order the SHS steel according to specific requirements.

Conclusion

Square Hollow Section steel, known for its strength and versatility, is the most used variant in a majority of industries. Square Hollow Section steel offers durability, longevity, and cost-effectiveness, making it an excellent choice whenever projects require properties such as high strength, lightweight design, and ease of installation for structural purposes. SHS steel can make that much-needed reliability in construction for building structures, machinery, or infrastructure for your project.