Introduction

Set screws play a vital role in various mechanical and engineering applications, providing the means to secure two components together with precision. Among the different types of set screws, the flat point set screw stands out as a versatile and unique choice. In this article, we will delve into the world of flat point set screw, exploring their characteristics, applications, advantages, and answering frequently asked questions to help you understand their significance in the fastener world.

What is a Flat Point Set Screw?

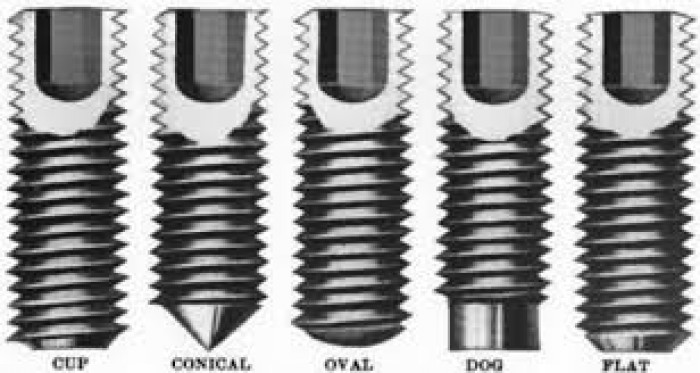

A flat point set screw is a specific type of set screw with a flat, blunt tip, as opposed to the more common pointed or cup-pointed set screws. This flat tip design ensures a secure hold while minimizing damage to the contacting surface. Flat point set screws are typically made of materials such as steel, stainless steel, or brass, and they come in various sizes and thread types to suit diverse applications.

Advantages of Flat Point Set Screws

1. Surface Protection

One of the primary advantages of using flat point set screws is their ability to protect the mating surface. The flat tip distributes pressure evenly, reducing the likelihood of damage or indentations, which can be a concern with pointed set screws. This makes them ideal for applications where surface preservation is crucial, such as in woodworking, electronics, and delicate machinery.

2. Excellent Holding Power

Flat point set screws provide excellent holding power due to their larger contact area. The flat tip evenly distributes the force applied, creating a secure and stable connection. This is especially valuable in applications where vibration or lateral movement is a concern.

3. Versatility

Flat point set screws are versatile fasteners that can be used in a wide range of applications. From securing pulleys and gears in machinery to holding electronic components in place, their adaptability is a key asset. You can find them in various materials, lengths, and thread sizes, making it easier to find the perfect fit for your specific needs.

Applications of Flat Point Set Screws

1. Woodworking

In the world of woodworking, flat point set screws are essential for attaching knobs, handles, and other hardware to wooden surfaces. They provide a secure hold without damaging the wood, ensuring a professional and polished finish.

2. Electronics

Flat point set screws are frequently used in electronic devices and circuitry. They are essential for securing components on circuit boards without risking damage. Their non-penetrating design makes them perfect for this purpose.

3. Machinery

Machinery and mechanical systems rely on flat point set screws to secure various components like pulleys, gears, and sprockets. The even distribution of pressure ensures that these components remain in place, even under heavy loads or high levels of vibration.

4. Aerospace

In the aerospace industry, precision and reliability are paramount. Flat point set screws are used in aircraft and spacecraft to secure critical components and minimize the risk of surface damage. Their holding power is crucial in these applications.

Frequently Asked Questions

1. How do I choose the right size of flat point set screw for my application?

Selecting the appropriate size of flat point set screw depends on various factors, including the material being fastened, the required holding power, and the available space. Consider the thread size, length, and material of the screw. If you're unsure, consult with a fastener expert or refer to industry standards and guidelines.

2. Are flat point set screws reusable?

Yes, flat point set screws are typically reusable if they are not damaged during removal. It's important to inspect the screw and the surface it was in contact with to ensure that there is no significant wear or damage. If both are in good condition, the screw can be reused.

3. Can flat point set screws be used in high-temperature environments?

The suitability of flat point set screws for high-temperature environments depends on the material they are made of. Stainless steel flat point set screws, for instance, can withstand higher temperatures compared to steel set screws. Be sure to check the material's temperature rating and choose a screw that is appropriate for your specific application.

4. What is the torque requirement for tightening a flat point set screw?

The torque requirement for tightening a flat point set screw varies based on the screw's size, material, and the specific application. It's essential to follow manufacturer recommendations or industry standards to ensure the correct torque is applied. Using a torque wrench is a common practice to achieve precise torque values.

5. Are there any alternatives to flat point set screws for surface-sensitive applications?

Yes, there are alternatives, such as nylon-tipped set screws or socket set screws with a smooth, non-marring tip. These options can also be used in applications where preserving the surface is essential. However, the choice of fastener depends on the specific requirements of your project.

6. Can flat point set screws be used in outdoor or corrosive environments?

For outdoor or corrosive environments, it's crucial to select flat point set screws made from materials that are corrosion-resistant, such as stainless steel. Additionally, applying a suitable coating or lubricant can further enhance their resistance to environmental factors.

7. What is the difference between a flat point set screw and a cup point set screw?

The primary difference between a flat point set screw and a cup point set screw is the shape of the tip. A flat point set screw has a flat, blunt tip that evenly distributes pressure, making it ideal for surface-sensitive applications. In contrast, a cup point set screw has a concave or cup-shaped tip, which provides a strong grip on the mating surface.

Conclusion

Flat point set screws are essential fasteners with a unique design that offers several advantages, including surface protection, excellent holding power, and versatility. Their applications span a wide range of industries, from woodworking and electronics to aerospace and machinery. Understanding their characteristics and how to choose the right one for your needs is crucial for successful fastening. With this knowledge and answers to frequently asked questions, you are better equipped to make informed decisions when it comes to incorporating flat point set screws into your projects.