The modern food industry is a dynamic and competitive landscape, where businesses of all sizes strive to meet consumer demands for freshness, quality, and convenience. In this fast-paced environment, efficient packaging and preservation solutions are essential for maintaining product integrity, minimizing waste, and enhancing customer satisfaction. Among the many tools available to food businesses, cup sealer, and vacuum sealer machines stand out as indispensable assets. These versatile machines offer reliable methods for sealing and preserving a wide range of food and beverage products, from individual servings of yogurt and salad dressing to bulk quantities of meats and produce.

In this comprehensive guide, we explore the functionalities, benefits, considerations, and applications of cup sealer and vacuum sealer machines, empowering businesses to make informed decisions and optimize their operations.

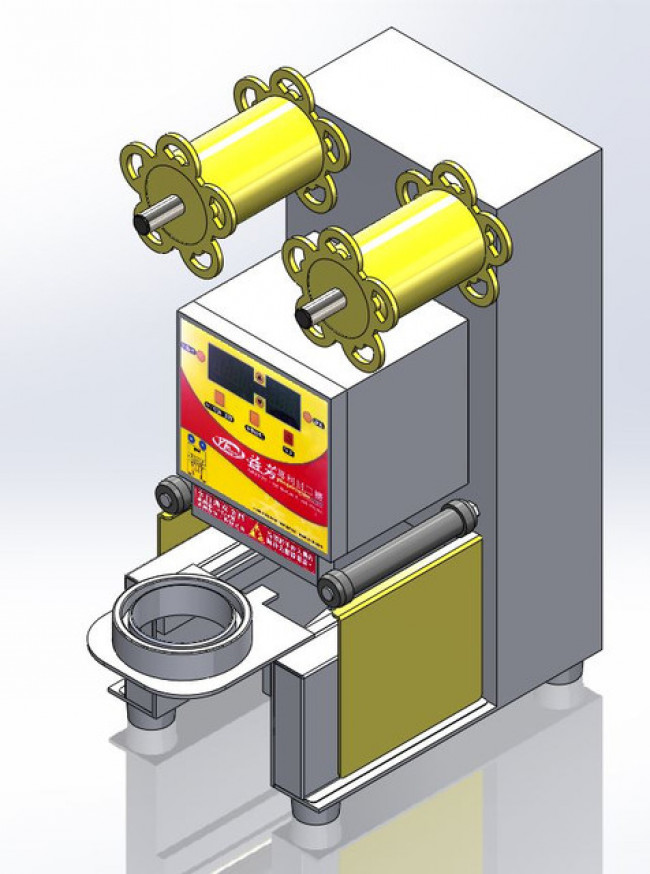

Cup Sealer Machines: Enhancing Freshness And Presentation

Cup sealer machines have become ubiquitous in food and beverage establishments, providing a convenient and efficient solution for sealing various types of containers, particularly cups. Whether you're packaging yogurt, fruit juice, salad dressing, or any other liquid or semi-liquid product, a cup sealer machine ensures a secure and hygienic seal that preserves freshness and enhances presentation.

How Cup Sealer Machines Work

At the heart of every cup sealer machine lies a simple yet effective mechanism that combines heat and pressure to seal cups with a layer of film or foil. The process is remarkably straightforward: place the filled cup onto the machine's platform, and the sealer will automatically apply the sealing material before swiftly sealing it shut. With precision and consistency, cup sealer machines ensure that each product is securely sealed, protecting it from contamination and extending its shelf life.

Benefits of Cup Sealer Machines

Preservation of Freshness: By creating an airtight seal, cup sealer machines help extend the shelf life of perishable goods, keeping them fresh for longer periods.

Hygiene and Safety: Sealed cups reduce the risk of contamination, ensuring that your products maintain their quality and meet food safety standards.

Enhanced Brand Image: A neatly sealed cup not only preserves the contents but also enhances the overall presentation, reflecting positively on your brand's image.

Cost-Efficiency: By minimizing product wastage due to spoilage or spills, cup sealer machines contribute to cost savings in the long run.

Considerations When Choosing A Cup Sealer Machine

Capacity: Evaluate your business's production volume to determine the appropriate capacity of the cup sealer machine. Whether you're a small-scale operation or a high-volume enterprise, there's a machine size and speed to suit your needs.

Sealing Material: Cup sealer machines may accommodate various types of sealing materials, including plastic film and aluminum foil. Consider the compatibility of the machine with your preferred packaging materials and the specific requirements of your products.

Ease of Maintenance: Opt for a machine that is easy to clean and maintain to ensure smooth operations and longevity. Regular maintenance and cleaning routines are essential for maximizing the lifespan of your cup sealer machine and minimizing downtime.

Vacuum Sealer Machines: Extending Shelf Life and Minimizing Waste

Vacuum sealer machines are a staple in food production, preservation, and storage facilities, offering a reliable method for extending the shelf life of perishable goods and minimizing food waste. By removing air from packaging before sealing it, these machines create a vacuum-sealed environment that inhibits the growth of microorganisms and slows down the degradation of food.

How Vacuum Sealer Machines Work

Vacuum sealer machines operate on a simple yet effective principle: they remove air from specially designed bags or containers and then seal them shut. By eliminating oxygen, moisture, and other factors that contribute to food spoilage, vacuum-sealed packaging preserves the quality and freshness of the packaged items, thereby prolonging their shelf life.

Benefits of Vacuum Sealer Machines

Extended Shelf Life: Vacuum sealing helps prolong the shelf life of perishable goods, reducing the likelihood of spoilage and minimizing food waste.

Preservation of Flavor and Nutrients: By sealing food in an airtight environment, vacuum sealer machines help retain the flavor, texture, and nutritional value of the packaged items.

Bulk Packaging: Vacuum sealing allows for efficient storage of bulk quantities of food, optimizing space and facilitating inventory management.

Marination and Sous Vide Cooking: Vacuum-sealed bags are ideal for marinating meats and vegetables, as well as for sous vide cooking, which involves cooking food in a precisely controlled water bath.

Considerations When Choosing a Vacuum Sealer Machine

Type of Sealing: Vacuum sealer machines may offer different types of sealing mechanisms, including single-seal or double-seal options. Consider the intended use of the machine and the level of sealing precision required for your products.

Bag Compatibility: Ensure that the machine is compatible with the type and size of bags you intend to use for packaging. Whether you're using pre-made bags or rolls of vacuum-sealing material, compatibility is essential for achieving reliable seals.

Additional Features: Some vacuum sealer machines come with additional features such as adjustable sealing settings, pulse vacuum function, and compatibility with accessories like jar sealers and bottle stoppers. Evaluate the available features based on your specific needs and preferences to find a machine that meets your requirements.

Applications of Cup Sealer and Vacuum Sealer Machines

The versatility of cup sealer and vacuum sealer machines extends beyond traditional food packaging applications. From commercial kitchens to food production facilities, these machines find numerous applications in various industries:

Hospitality: Hotels, resorts, and catering services use cup sealer machines to package individual servings of condiments, sauces, and beverages, ensuring portion control and hygiene compliance.

Retail: Grocery stores, delis, and specialty food shops utilize vacuum sealer machines to package and preserve fresh produce, cheeses, and meats, enhancing product presentation and extending shelf life.

Healthcare: Hospitals, clinics, and long-term care facilities rely on vacuum sealer machines to package and store sterile medical supplies, pharmaceuticals, and patient meals, maintaining hygiene standards and preventing contamination.

Manufacturing: Food manufacturers and processing plants use cup sealer machines to package ready-to-eat meals, snacks, and convenience foods, streamlining production and ensuring product quality and consistency.

E-commerce: Online food delivery services and meal kit companies leverage vacuum sealer machines to package and ship perishable goods to customers, preserving freshness during transit and reducing food waste.

Wrapping it Up

Cup sealer and vacuum sealer machines are indispensable assets for businesses in the food industry, offering efficient solutions for packaging, preservation, and storage. Whether you're sealing cups of yogurt or vacuum-packing cuts of meat, these machines play a crucial role in maintaining product freshness, minimizing waste, and enhancing customer satisfaction. By understanding their functionalities, benefits, considerations, and applications, you can make informed decisions when selecting the right equipment for your food business. Invest in quality cup sealer and vacuum sealer machines today to elevate your operations and stay ahead in the competitive marketplace.